Unravel Knotty Problems: A Friendly Guide to Basic Rope Care & Maintenance

Rope. It’s a surprisingly versatile tool, isn’t it? From securing loads and hoisting sails to crafting macramé and providing essential support in countless applications, rope has been a cornerstone of human ingenuity for millennia. But like any tool, rope needs care and maintenance to perform reliably and safely. Ignoring these needs can lead to premature failure, potentially with serious consequences. This guide will walk you through the basics of rope care, covering everything from understanding different rope materials to cleaning, storing, and inspecting for wear and tear. We’ll keep it friendly and accessible – no need to be a seasoned sailor to keep your ropes in tip-top shape!

Understanding Your Rope: Materials Matter

Before we dive into care routines, let’s quickly look at common rope materials. Each has its strengths and weaknesses, influencing how you should treat it.

- Natural Fiber Ropes (Manila, Sisal, Cotton): These are traditional, biodegradable options. They’re relatively inexpensive but susceptible to rot, mildew, and abrasion. They lose strength when wet and require more frequent maintenance. Manila, made from abaca plant fibers, is probably the most recognizable.

- Synthetic Fiber Ropes (Nylon, Polyester, Polypropylene, Dyneema/Spectra): These have largely replaced natural fibers in many applications due to their superior strength, durability, and resistance to the elements.

- Nylon: Excellent strength and elasticity (stretch). Good abrasion resistance, but loses some strength when wet. Commonly used for mooring lines and shock absorption.

- Polyester: Lower stretch than nylon, excellent resistance to UV degradation and abrasion. Holds its strength well when wet. Great for sheets and halyards on sailboats.

- Polypropylene: Lightweight and floats! Not as strong as nylon or polyester, and degrades in sunlight. Good for water sports and general utility.

- Dyneema/Spectra (UHMWPE): Exceptionally strong and lightweight. Low stretch and excellent abrasion resistance. Expensive, but worth it for high-performance applications.

- Blended Ropes: Combinations of materials to achieve specific properties.

Knowing your rope’s material is the first step in providing the correct care. Check the manufacturer’s label or documentation if you’re unsure.

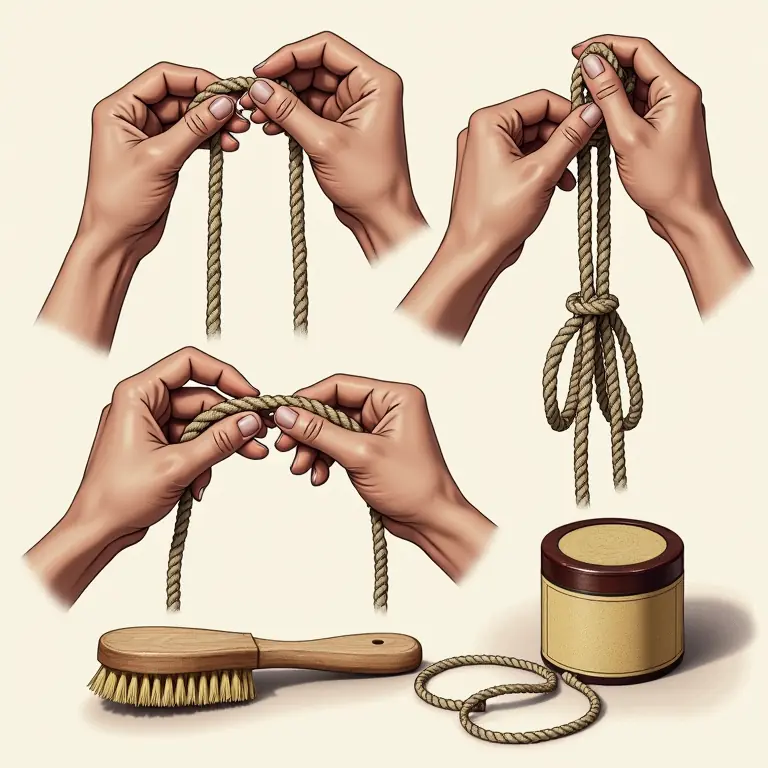

Cleaning Your Rope: Keeping it Fresh

Dirt, grime, salt, chemicals, and UV exposure all take a toll on rope. Regular cleaning helps prevent deterioration and extends its lifespan. The cleaning method depends on the rope material and the type of contamination.

Natural Fiber Rope Cleaning

Natural fiber ropes require the most attention. Saltwater is particularly damaging, so thorough rinsing after marine use is crucial. Here’s how to clean them:

- Rinse: Flush with fresh water to remove salt, dirt, and debris.

- Wash: Use a mild soap (like a gentle dish soap) and a soft brush to scrub the rope. Avoid harsh detergents or bleach.

- Rinse Again: Ensure all soap residue is removed.

- Dry: Allow the rope to air dry *completely* in a well-ventilated area, away from direct sunlight. Do not use heat, as this can damage the fibers.

For stubborn stains or mildew, a diluted solution of water and white vinegar can be used, followed by a thorough rinse.

Synthetic Fiber Rope Cleaning

Synthetic ropes are more resilient, but still benefit from regular cleaning.

- Rinse: Flush with fresh water, especially after saltwater exposure.

- Wash: Use a mild soap and a soft brush. Some synthetic ropes can tolerate a slightly stronger detergent, but always test in an inconspicuous area first.

- Rinse Again: Remove all soap residue.

- Dry: Air dry in a well-ventilated area, away from direct sunlight.

For oily or greasy contamination, a solvent-based cleaner specifically designed for synthetic ropes may be necessary. Again, test first!

Inspection: Spotting Trouble Before it Happens

Regular inspection is arguably the most important aspect of rope care. Catching damage early can prevent catastrophic failures. Here’s what to look for:

- Abrasion: Look for worn spots, flattened fibers, or areas where the rope has been rubbed against a rough surface.

- Cutting: Check for cuts, nicks, or sharp edges caused by tools or objects.

- Kinking/Birdcaging: Severe kinks can weaken the rope. Birdcaging refers to internal twisting or distortion of the rope’s core.

- UV Degradation: Prolonged sun exposure can cause synthetic ropes to become brittle and lose strength. Look for discoloration or a chalky surface.

- Rot/Mildew (Natural Fibers): Check for dark spots, softness, or a musty odor.

- Core Damage: If the rope’s core is exposed or damaged, it’s significantly weakened.

- Heat Damage: Discoloration or melting indicates heat exposure.

- Discoloration/Chemical Damage: Any unusual discoloration or signs of chemical reaction.

When inspecting, run your hand along the entire length of the rope, feeling for any irregularities. A magnifying glass can be helpful for spotting subtle damage.

If you find any significant damage, retire the rope immediately. It’s simply not worth the risk.

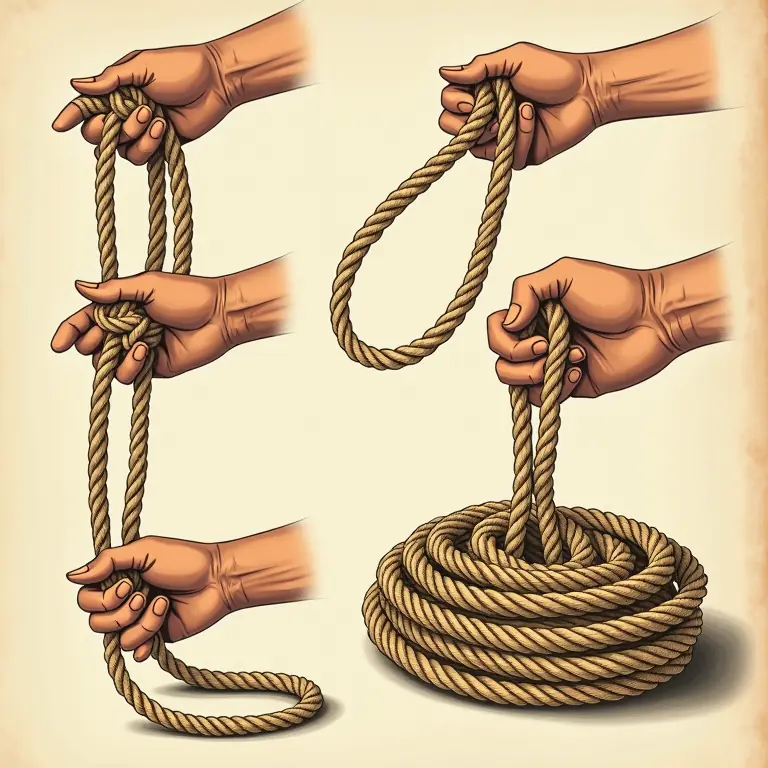

Proper Storage: Protecting Your Investment

How you store your rope significantly impacts its longevity. Proper storage protects it from the elements and prevents unnecessary wear and tear.

- Dry Storage: Always store rope in a dry location. Dampness promotes mildew and rot in natural fibers and can weaken synthetic ropes.

- UV Protection: Store rope away from direct sunlight. UV radiation degrades synthetic materials.

- Ventilation: Ensure good air circulation to prevent moisture buildup.

- Coiling vs. Flaking: For long-term storage, flaking is generally preferred over coiling. Flaking involves laying the rope in a figure-eight pattern, which minimizes kinking. Coiling can create internal stress and lead to distortion.

- Rope Bags: Use a dedicated rope bag to protect the rope from dirt, abrasion, and UV exposure.

- Avoid Chemical Contact: Store rope away from chemicals, solvents, and fuels.

Don’t just toss your rope into a pile! A little organization goes a long way.

Specific Considerations for Different Rope Types

Manila Rope

Manila requires the most diligent care. Keep it dry, protect it from abrasion, and regularly inspect for rot. Consider treating it with a preservative specifically designed for natural fibers.

Nylon Rope

While strong, nylon stretches and can lose strength when wet. Avoid prolonged exposure to sunlight. Regular cleaning and inspection are essential.

Polyester Rope

Polyester is a workhorse. It’s relatively low-maintenance, but still benefits from regular cleaning and inspection. Its resistance to UV degradation makes it a good choice for outdoor applications.

Polypropylene Rope

Polypropylene is lightweight and floats, but it’s not as strong as other synthetics. Protect it from sunlight and abrasion. It’s a good choice for temporary uses.

Dyneema/Spectra Rope

This high-performance rope is expensive, so proper care is vital. Avoid sharp bends and abrasion. Follow the manufacturer’s recommendations for cleaning and storage.

Rope and Safety: A Final Word

Rope is a powerful tool, but it’s not foolproof. Always use the correct rope for the job, and always follow safe working practices. Never exceed the rope’s working load limit. Regular inspection and maintenance are essential for ensuring safety.

Taking the time to care for your ropes will not only extend their lifespan but also ensure their reliability when you need them most. A little preventative maintenance can save you time, money, and potentially, a lot of trouble.

If you’re interested in learning more about responsible resource allocation, you might find this article on charitable giving helpful. Thinking about the longevity of tools aligns with mindful consumption.

For those fascinated by the natural world and its sounds, exploring birdsong identification offers a different kind of appreciation for resilience and careful observation.

And if you’re looking for tips on preserving other everyday items, check out this guide to textile conservation.

Discussion about this post