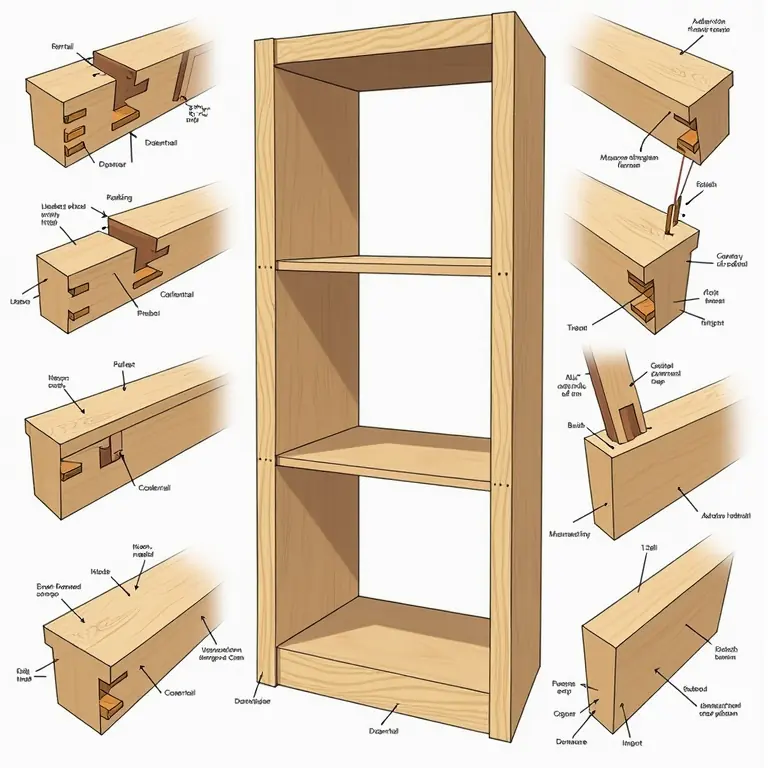

Build a Better Bookshelf: A Friendly Guide to Wood Joining Techniques

So, you’re thinking about building a bookshelf? Fantastic! It’s a rewarding project, and a great way to learn some fundamental woodworking skills. But before you even *think* about picking up a nail or screw, you need to understand how to join wood together. This isn’t just about making something that stands up; it’s about creating something durable, beautiful, and that will last for years to come. This guide will walk you through a variety of wood joining techniques, from the simplest to the more complex, helping you choose the best method for your bookshelf – and future projects!

Why Joinery Matters: Beyond Just Holding Wood Together

It’s easy to think of wood joining as simply gluing or screwing two pieces of wood together. And while those *are* methods, true joinery goes much deeper. Good joinery adds strength, stability, and aesthetic appeal. A well-executed joint can be a beautiful feature in itself, showcasing craftsmanship. A poorly executed one… well, let’s just say bookshelves have a habit of collapsing when the joints aren’t up to snuff. We want to avoid that! Factors like the type of wood, the load the joint will bear, and the desired look all play a role in selecting the right technique. This guide will cover options for all skill levels and project needs.

The Simplest Solutions: Screws, Nails, and Pocket Holes

Let’s start with the easy stuff. These methods are perfect for beginners and quick projects. They require minimal tools and are relatively forgiving.

Screws: The Workhorse of Wood Joining

Screws are incredibly versatile. Different screw types are suited for different applications. Wood screws, for example, have a coarser thread than machine screws and are designed to bite into wood fibers. Before screwing, always pre-drill a pilot hole – this prevents the wood from splitting, especially with hardwoods. The pilot hole should be slightly smaller than the screw’s core diameter. Countersinking the screw ensures the head sits flush with the surface, giving a cleaner look. For a bookshelf, screws are great for attaching the back panel or reinforcing weaker joints.

Nails: Quick and Easy, But Not Always the Strongest

Nails are fast, but generally not as strong as screws. They work best for less structural elements, like attaching trim or temporarily holding pieces together while glue dries. Like screws, pre-drilling can prevent splitting, especially near the edges of the wood. Different nail types – finishing nails, box nails, etc. – have different applications. Finishing nails, with their small heads, are ideal for a clean, hidden look.

Pocket Hole Joinery: A Beginner-Friendly Game Changer

Pocket hole joinery uses a specialized jig to drill angled holes into one piece of wood. These holes receive self-tapping screws that draw the two pieces together. It’s fast, strong, and doesn’t require precise alignment. It’s *fantastic* for building frames and boxes. While the pocket holes are visible, they can be filled with wood plugs for a more refined appearance. A pocket hole jig is a relatively inexpensive investment that will dramatically improve your woodworking capabilities.

Stepping Up: Traditional Wood Joints

Now we’re getting into the techniques that have been used by woodworkers for centuries. These joints require more precision and skill, but they create incredibly strong and beautiful connections.

The Butt Joint: Simple, But Requires Reinforcement

The butt joint is the simplest of all joints – literally just butting two pieces of wood together. It’s weak on its own and *always* needs reinforcement. This can be done with screws, nails, dowels, or other joinery techniques. It’s often used as a starting point for more complex joints.

The Lap Joint: Increased Surface Area, Increased Strength

A lap joint involves overlapping two pieces of wood and then gluing and screwing or nailing them together. This increased surface area provides a much stronger connection than a butt joint. There are several variations, including half-lap joints (where half the thickness of each piece is removed) and full-lap joints (where the full thickness is used). Lap joints are great for frame construction.

The Dado Joint: Shelves That Won’t Budge

A dado joint is a groove cut into one piece of wood to receive another. It’s an excellent way to create strong, stable shelves. The groove can be cut with a router, table saw, or even a hand saw (though that’s more challenging). The fit should be snug, but not too tight, allowing for glue to be applied. Dado joints are a cornerstone of bookshelf construction.

The Rabbet Joint: A Variation on the Dado

Similar to a dado, a rabbet joint involves cutting a recess along the *edge* of a piece of wood. This is often used to create a frame around a panel or to join the sides of a box. Like the dado, it provides a strong and stable connection.

The Mortise and Tenon Joint: The King of Wood Joints

The mortise and tenon joint is considered the strongest and most elegant of traditional wood joints. It involves cutting a mortise (a hole) into one piece of wood and a tenon (a projecting tongue) on the other. The tenon fits snugly into the mortise, creating a remarkably strong connection. There are many variations, including through-tenons (where the tenon extends through the mortise) and wedged tenons (where wedges are driven into the tenon to lock it in place). This joint requires precision and patience, but the results are well worth the effort.

Advanced Techniques: For the Dedicated Woodworker

These joints require a significant investment in tools and skill, but they offer unparalleled strength and beauty.

The Dovetail Joint: A Sign of True Craftsmanship

The dovetail joint is renowned for its interlocking, fan-shaped pins and tails. It’s incredibly strong and visually striking. Dovetails can be cut by hand (a true test of skill) or with a dovetail jig. They’re commonly used for drawers, boxes, and other applications where strength and durability are paramount. A well-executed dovetail joint is a mark of a master woodworker.

The Miter Joint: Seamless Corners

A miter joint involves cutting two pieces of wood at an angle (usually 45 degrees) and joining them together to form a corner. It’s often used for picture frames, trim, and decorative elements. While visually appealing, miter joints are relatively weak on their own and usually require reinforcement with splines, biscuits, or other joinery techniques.

Glue: The Unsung Hero of Wood Joining

No matter which joinery technique you choose, glue is essential. There are several types of wood glue, each with its own advantages and disadvantages.

- Yellow Wood Glue (PVA): The most common type of wood glue. It’s strong, affordable, and easy to use.

- Polyurethane Glue: Waterproof and can fill gaps. It expands as it dries, making it useful for less-than-perfect fits.

- Epoxy: Extremely strong and waterproof. It’s more expensive than other glues and requires more careful mixing.

Always follow the manufacturer’s instructions for clamping time and open time. Clamps are crucial for applying even pressure and ensuring a strong bond.

Choosing the Right Joint for Your Bookshelf

Okay, so with all these options, which joint should *you* use for your bookshelf? Here’s a quick guide:

- Simple Bookshelf (beginner): Pocket hole joinery, screws, and glue.

- Sturdy Bookshelf (intermediate): Dado joints for shelves, lap joints for the frame, reinforced with screws and glue.

- High-End Bookshelf (advanced): Mortise and tenon joints for the frame, dovetail joints for drawers (if applicable), and meticulous glue-up.

Resources for Further Learning

This guide is just a starting point. There are countless resources available to help you expand your woodworking knowledge.

- Online Forums: WoodworkingTalk, LumberJocks

- YouTube Channels: Steve Ramsey – Woodworking for Mere Mortals, The Wood Whisperer

- Books: “Understanding Wood Finishing” by Bob Flexner, “The Complete Manual of Woodworking” by Albert Jackson and David Day

And don’t forget to explore other crafting techniques! Maybe you’ll find yourself inspired to weave wonderful baskets or sharpen your skills with knife sharpening. Woodworking often leads to a love of all things handmade.

Safety First!

Before you start any woodworking project, always prioritize safety. Wear safety glasses, a dust mask, and hearing protection. Follow the manufacturer’s instructions for all tools. And remember, take your time and be careful!

Finally, remember that building a bookshelf is a journey, not just a destination. Embrace the learning process, experiment with different techniques, and enjoy the satisfaction of creating something beautiful and functional with your own two hands. And if you’re feeling inspired to tackle other DIY projects, why not build your own rain barrel?

Discussion about this post